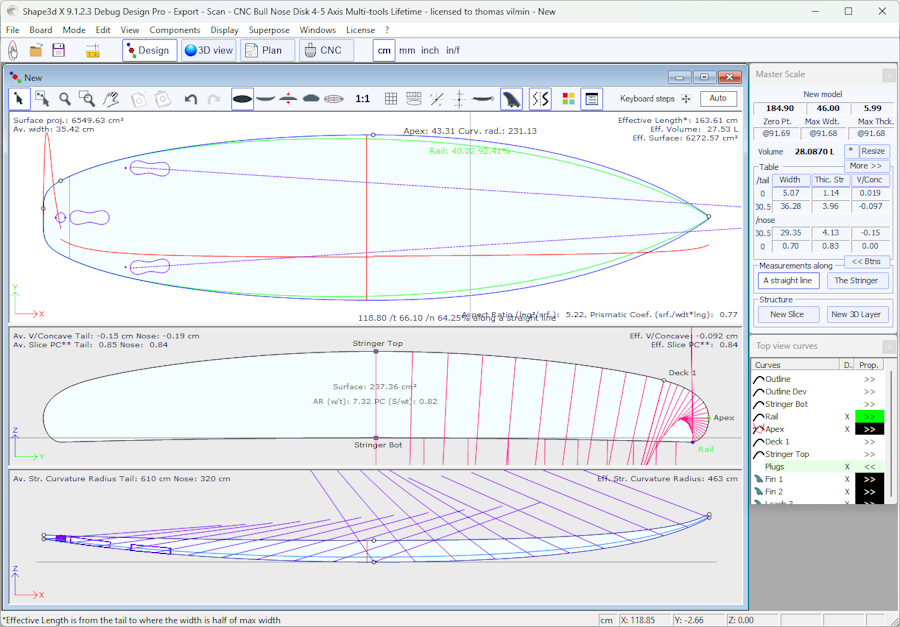

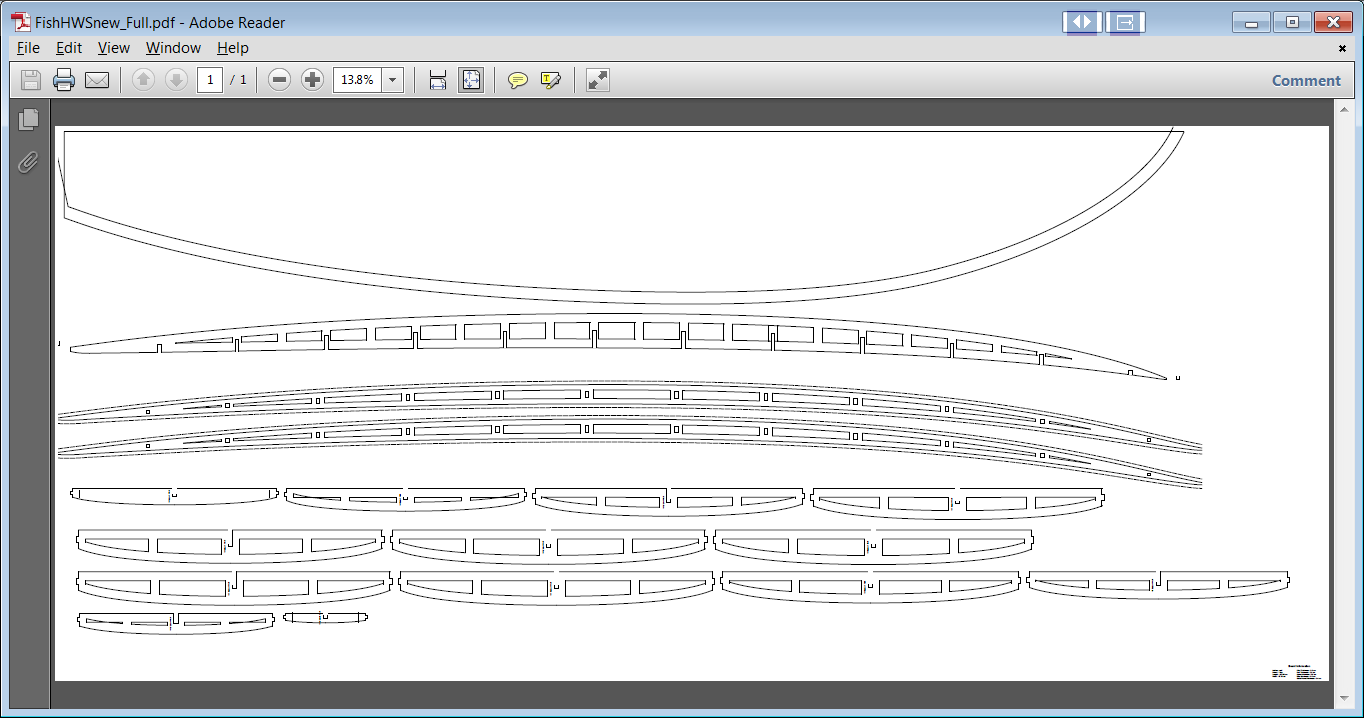

It saves shapers a little bit of time, and helps to ensure that they can get better results when duplicating certain models. This is the stage that a machine cut will get you to, as opposed to taking an electric planer and doing it by hand. Now, most of the detailed shaping comes after a board has been roughed out. That’s where the majority of skill comes into play, and that’s not even counting the glassing process, which is a whole other level in itself. But you’re not done there, you still have to finish shape it to perfection. If you have never played around with a CAD file, go download a free program like Shape3D or AKU Shaper, design a board, and see how it really turns out when it comes out of the machine. You have to know these principles and theories, and you have to be able to hand shape at a high level to get even a decent design out of a CAD file and a machine cut. But in reality, you still have to have an understanding of how and why boards and design principles work. Sure, anyone CAN do it, just like anyone CAN get a blank and some tools and hack their own board out. And that this in turn could hurt the industry as we know it, taking jobs away from the craftsmen that have dedicated years into their practice.

One of the biggest fears about the machine is that anyone can go and “pop-out” boards on a whim.

#FREE AKU SHAPER FILES HOW TO#

Here’s the thing with the CNC and CAD programs though: you still have to be a skilled shaper by hand to know how to design a good board on a computer and finish one that was cut on a machine.

0 kommentar(er)

0 kommentar(er)